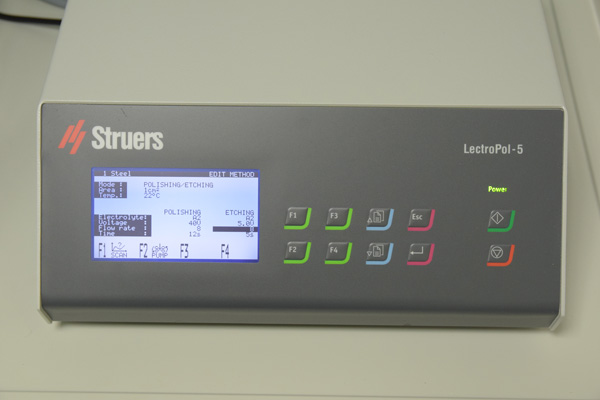

Electrolytical polisher Lectropol 5

Guarantor

Description

Machine for automatic micro-processor controlled electrolytical polishing and etching of metallographic specimens. Lectropol5 is equipped with a scanning function, i.e. a pre-defined voltage range is scanned to determine the current density curve. This curve is used to define the correct voltage for polishing and etching. The machine features database with methods for various types of materials. LectroPol-5 is equipped with a built-in measuring and control system, constantly monitoring the electrolyte temperature. Inseparable part of the instrument setup is a recirculating chiller Lauda RP 870, capable of providing electrolyte temperature down to –20 °C.

The sample surface to be polished is exposed to electrolyte through an opening in a mask (standard operation) or by immersion into it in a stainless steel dish (external extching cell).

Photogallery

Specification

Output voltage/current

| Regime | Voltage | Current |

|---|

| Polishing | 0–120V | (1V steps) / 6A |

| Etching | 0–25V | (0.5V steps) / 6A |

| External Etching | 0–15V | (0.5V steps) / 1.5A |

Software and electronics

| Display | 128 × 240 dots (16 × 40 characters) |

|---|

| Controls | touch pad |

|---|

| Database | 10 built-in Struers methods + 20 user definable methods |

|---|

Standard consumables

| Electrolyte | Applicable to: |

|---|

| A2 | Aluminium |

|---|

| Iron |

| Nickel |

| Silver |

| Stainless Steel |

| Steel |

| Tin |

| Titanium |

Other electrolytes shall only be brought in after approval!

| Mask opening | Area: |

|---|

| round | 0.5 cm2 |

| 1 cm2 |

| rectangular | 2 cm2 |

| 5 cm2 |

Custom shaped openings can be manufactured using a blind mask.