A precision machine is used to cut semiconductor wafers into individual chips or dice.

A programmable spindle speed and variable feed rate allow maximum dicing control and repeatability.

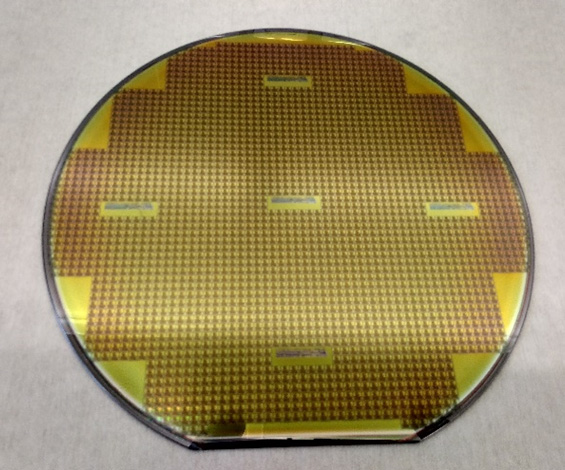

Wafers are held to chuck table by means of vacuum and chuck can accommodate circular and rectangular wafers.

An extremely thin diamond blade is used to dice, cut, or groove semiconductor wafers, silicon, glass, ceramic, crystal, and many other types of material.

| Wafer diameter | 25.4 mm – 152.4 mm (1" – 6") |

|---|---|

| Wafer thickness | 0.01–5.0 mm |

| Min. cut-width | 50 μm for Si wafer |

| Min. size of chip | 1x1 mm |

| X-axis (feed) | 240 mm |

| Y-axis (index) | 165 mm |

| Index step | 0.02–100 mm |

| Z-axis (verticle) | 10 mm |

| Rotation angle | 0.01–165 degrees |

| Spindle speed | 15,000–50,000 rpm |